INQUIRY CREATES POSSIBILITIES

-

ONE OF THE BEST STEEL WIRE IN ASIA

-

Cold Forging Applications: Chain • Bushing • Roller • Pin • etc.

We have decades of experience in cold forging of chains and automotive parts.Cold forging is an impact forming process that plastically deforms a piece of raw material, under high compressive force, between a punch and a die within suitable equipment such as a machine press.In essence, cold forging is a displacement process that forms existing material into the desired shape; contrast this with conventional machining, in which material is removed to create the desired shape. This distinction offers several significant advantages.

-

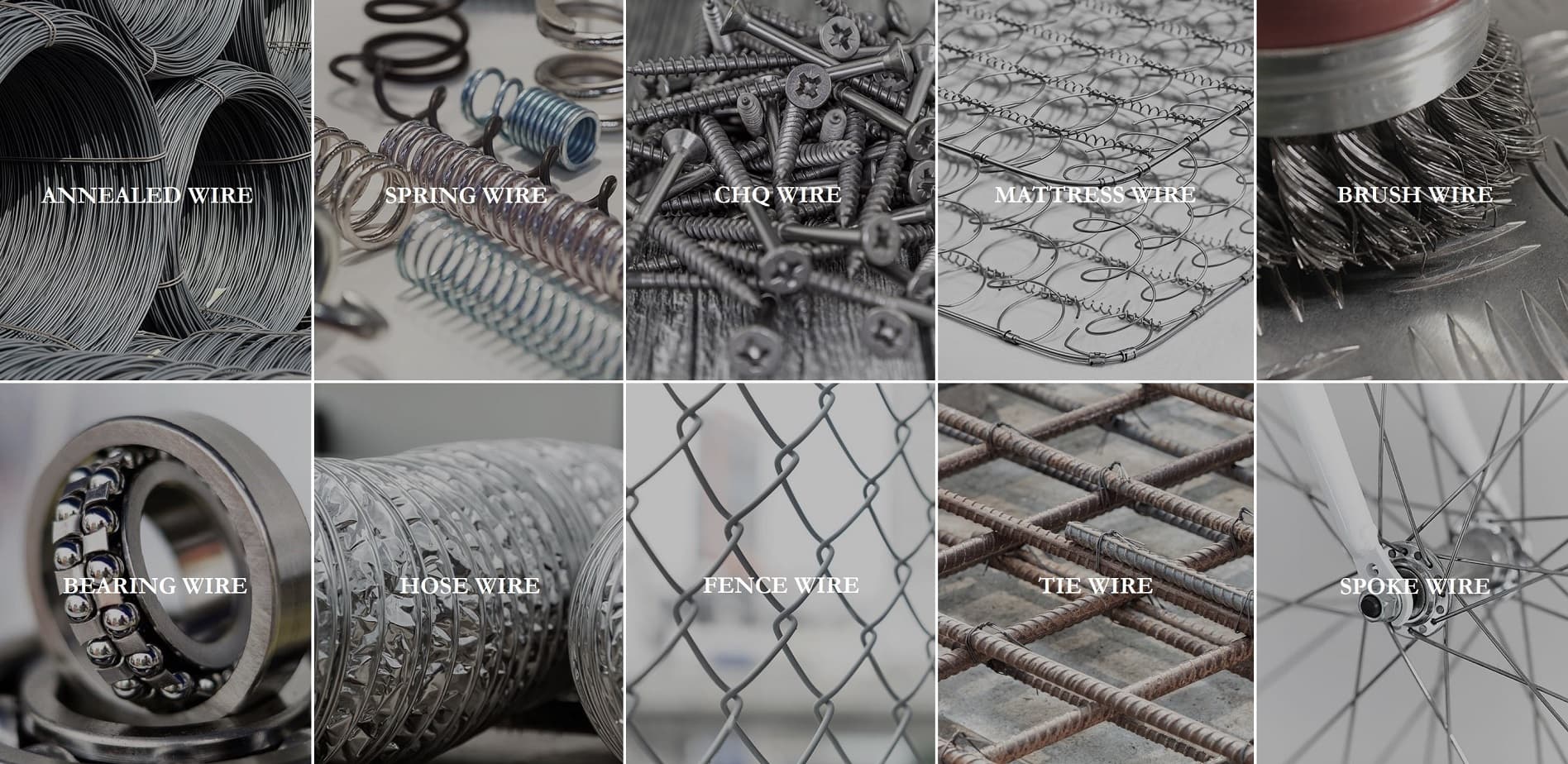

Wire Applications: Fastener • Spring • Brush • Tie for Rebar • etc.

We offers wide range of steel and alloy wire for manufacturing high strength steel bolts, screws, stud bolts, threaded rods, nuts, washers, accessories and customized bolting components. Carbon Steel Fasteners have high strength and are used for bolting oil and gas pipelines, structural joints, shipbuilding, automotives, etc. The medium carbon steel is mainly used to manufacture high-strength moving parts, such as air compressors, pump pistons, steam turbine impellers, heavy machinery shafts, worms, gears, etc.

-

Wire Applications : Fence • Mattress • Baling • Spoke • Hose • etc.

Our wire is available in low, medium and high carbon steel. Low carbon wire is available as bright and annealed with wire processing options that include cold heading and straighten and cut. Used primarily for components in applications such as the construction, fasteners, automotive. Medium and low carbon steel wire forms easily and can handle moderate flattening and bending.High carbon steel wire due to the higher carbon content, this carbon steel wire is stronger, but the toughness is worse than low carbon steel wire.

BEST SUPPLIER TO BORGWARNER FOR THREE CONSECUTIVE YEARS

EagleWires™Specification

- Carbon Steel Wire

- Alloy Steel Wire